Leakage

Solution

A data-driven approach to reducing leakage

Leakage detection is a vital but difficult task for utilities organizations. Our leakage solution provides a faster, better, data-driven approach for predicting and identifying assets that are at risk of losing product through leakage. Our unique rules-based approach and spatial machine learning capabilities learn to understand the relationships between assets and their environments, recognizing patterns not otherwise identified by traditional methods and tools.

The Challenge

We understand the increasing pressure on utilities to reduce the amount of product lost through  leakage, improve the reporting of leakage, and ultimately move towards a target of ‘zero leakage’.

leakage, improve the reporting of leakage, and ultimately move towards a target of ‘zero leakage’.

Loss of product through leakage is often calculated by large geographical areas such as District Metered Areas (DMA) or network zones. Once an area has been identified as having a high level of leakage, engineers then need to locate and repair the faulty assets. Although engineers often have large areas to investigate, the point of impairment is likely to be small, meaning that it could take several days to detect the leak. During this time costs accumulate from ongoing product losses, accumulated engineering hours, and the potential disruption to customers.

The Solution

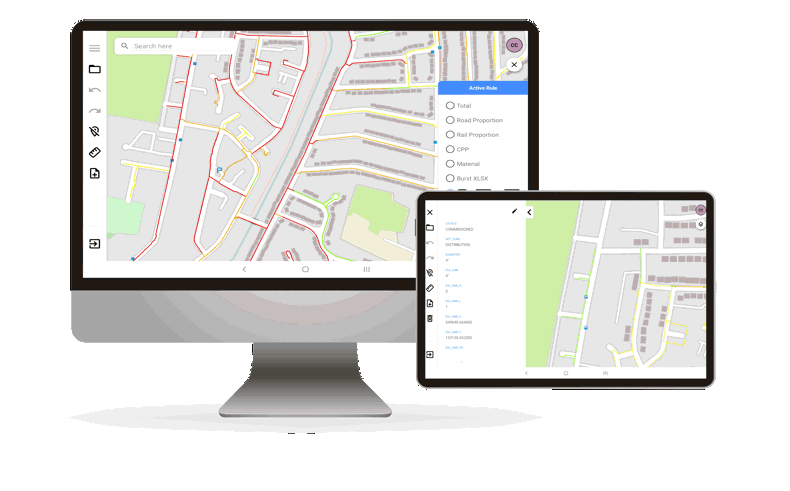

Our solution uses both 1Data Gateway and 1Integrate. 1Data Gateway is a cloud-enabled portal which allows the de-centralization of leakage machine learning processes, allowing users to submit data securely over the web. Powered by 1Integrate’s rules-engine, data is automatically checked and validated at source to ensure its completeness, quality, and reliability. When the users are happy with the quality of the data, it is prepared for the machine learning analysis.

The solution is data agnostic, allowing for the ingestion of a range of data inputs from which it can make sense of the proliferation of data, and recognising patterns not otherwise identified by traditional methods and tools that highlight those assets most likely to fail. These patterns produce geographical hotspots - sometimes known as “heat maps” - that allow you to predict leakage more reliably and subsequently prioritise maintenance better.

The Result

Our solution uses a rules-based approach and spatial machine learning capabilities to better predict assets that are most likely to fail and result in product losses through leakage.

Weighted totals of scores are used to represent the risk of leakage for pipes within DMAs to help you identify a prioritized list of high-risk leakage areas. These are visualized on a "heat map" to direct the most effective resources more efficiently and prioritize finding and fixing the biggest leaks.

By reducing the time taken to detect a leak, repairs can be made faster and the volume of product lost to leakage is minimized. This allows you to meet regulatory targets and service your customers in a more sustainable way.